DP Flow

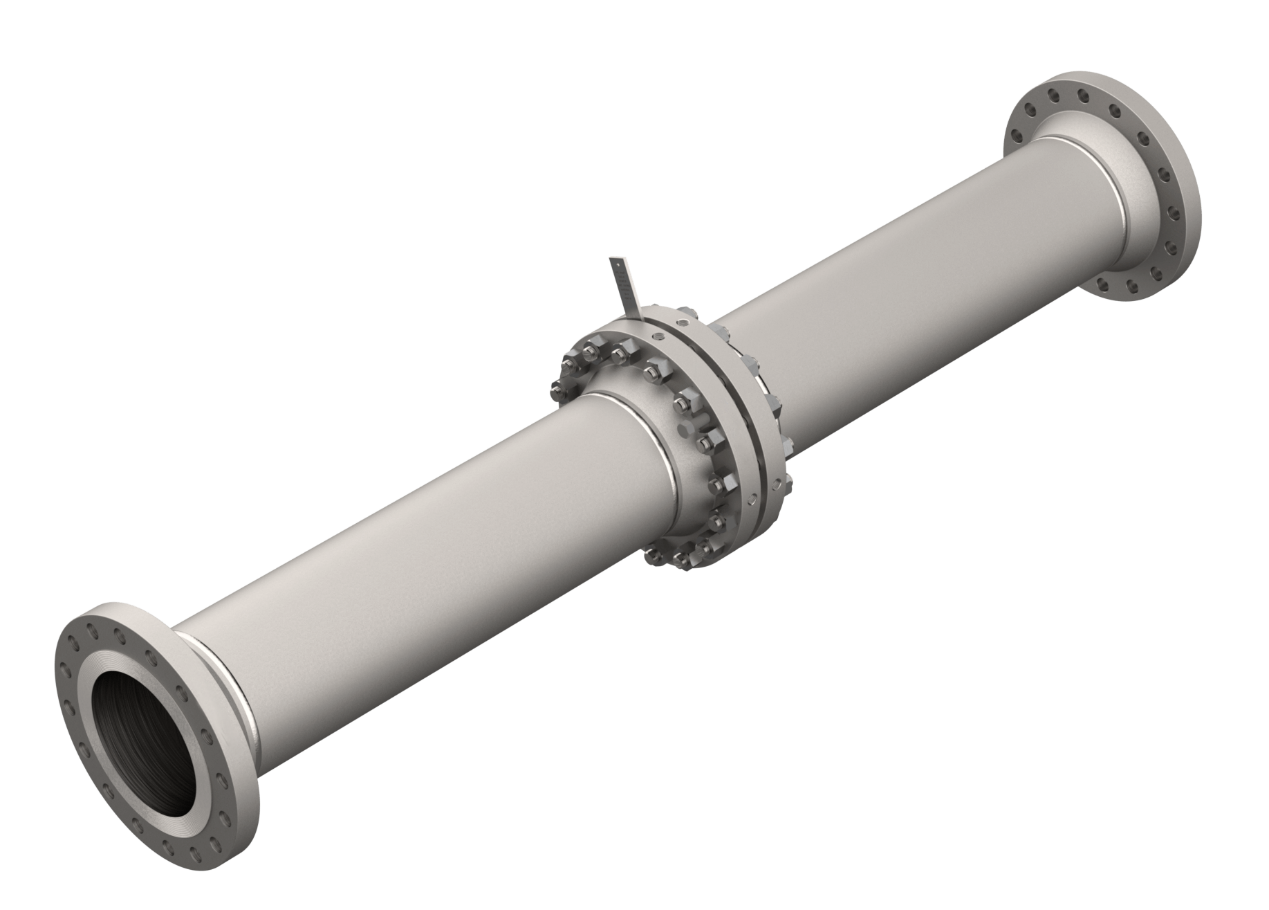

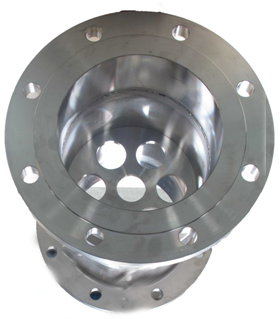

Orifice Plates

Orifice primary flow elements, flange unions, and holding block technologies offer optimum flexibility for applications with diverse piping schemes, ease of replacement, and a low capital investment. The orifice plate is one of the most common differential elements for measuring clean liquids, gases, and vapor (steam) flow.

AEEC application specialists can help you select from our wide range of stock product configurations, or our engineers can custom tailor a solution for your specific orifice flow meter requirements.

Wedge Flowmeters

Wedge flow meters are designed for highly viscous, slurry type, or contaminated line fluid applications, including difficult-to-meter, air entrained liquids, as well as particulate entrained, high viscosity, or slurry solutions. Examples of these applications include: raw sewage, sludge, tar sands, pulp mash, cement, liquid asphalt, and molten sulfur.

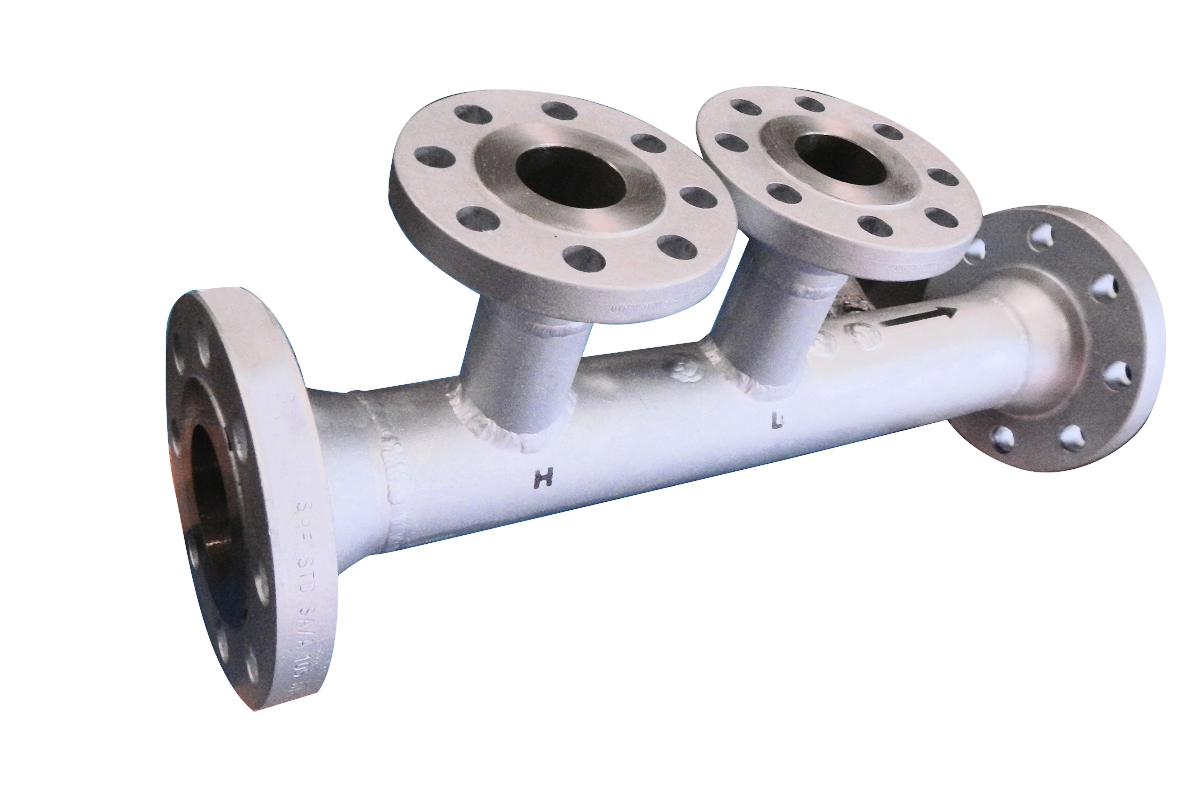

Rectangular Flowmeters

The AEEC Rectangular Flowmeter is a new type of differential pressure flow measurement device, which can be used to measure gases, vapors, liquids, high friction fluids (including solid particles) and highly corrosive fluids. It is a highly accurate and reliable flow measurement device, which makes the application of DP flow measurement technology more extensive and flexible.

The AEEC Rectangular Flowmeter is widely used in petroleum and petrochemical, metallurgy, energy, electric power, fine chemical and other industries for its excellent performance.

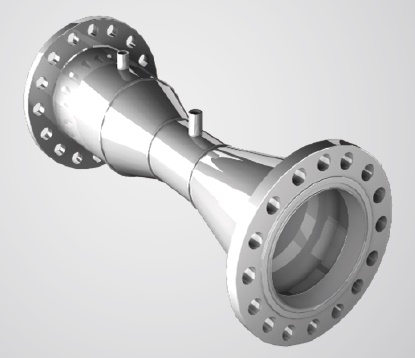

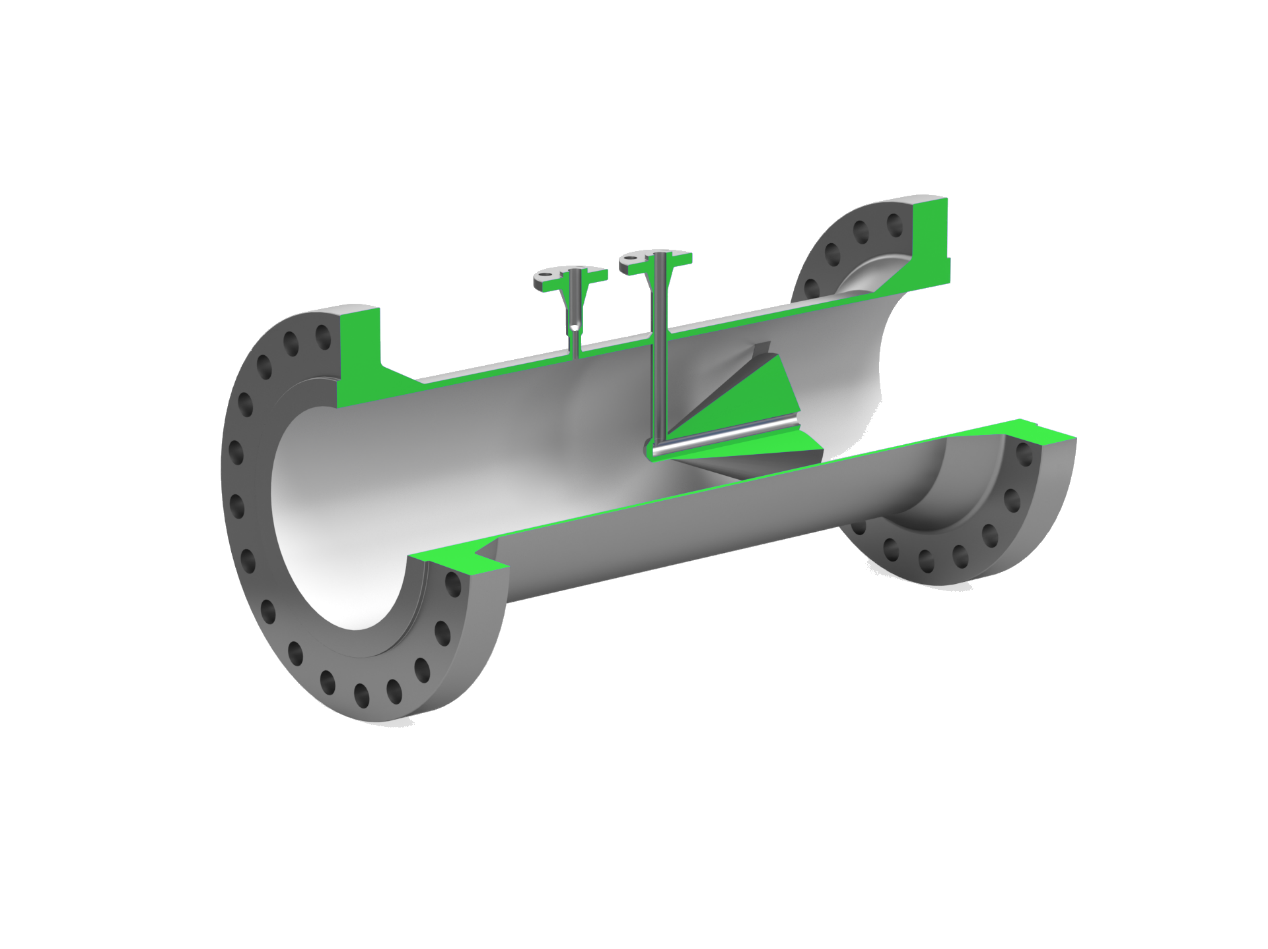

Venturi Flowmeters

The Classical Venturi flow meter design provides longer lasting accuracy and lower permanent pressure loss than orifice and nozzle style meters, reducing maintenance and operating costs. The Classical Venturi meter design is suitable for flow rate measurement of clean liquids, gases, and steam, particularly if low pressure loss is desired. Classical Venturi flow meter design provides longer lasting accuracy and lower permanent pressure loss than orifice type meters, reducing maintenance and operating costs. This meter is suitable for flow rate measurement of aggressive and non-aggressive liquids, gasses, and steam especially if low pressure loss is desired.

The Classical Venturi flow meter restricts the flow at its throat, increasing the velocity of the fluid, and measures the pressure difference of the unrestricted flow and restricted flow. The meter’s throat can be designed to meet the flow measurement application optimizing the meter’s accuracy and permanent pressure loss.The Classical Venturi flow meter restricts the flow at its throat, increasing the velocity of the fluid, and measures the pressure difference of the unrestricted flow and restricted flow. The meter’s throat can be designed to meet the flow measurement application optimizing the meter’s accuracy and permanent pressure loss.

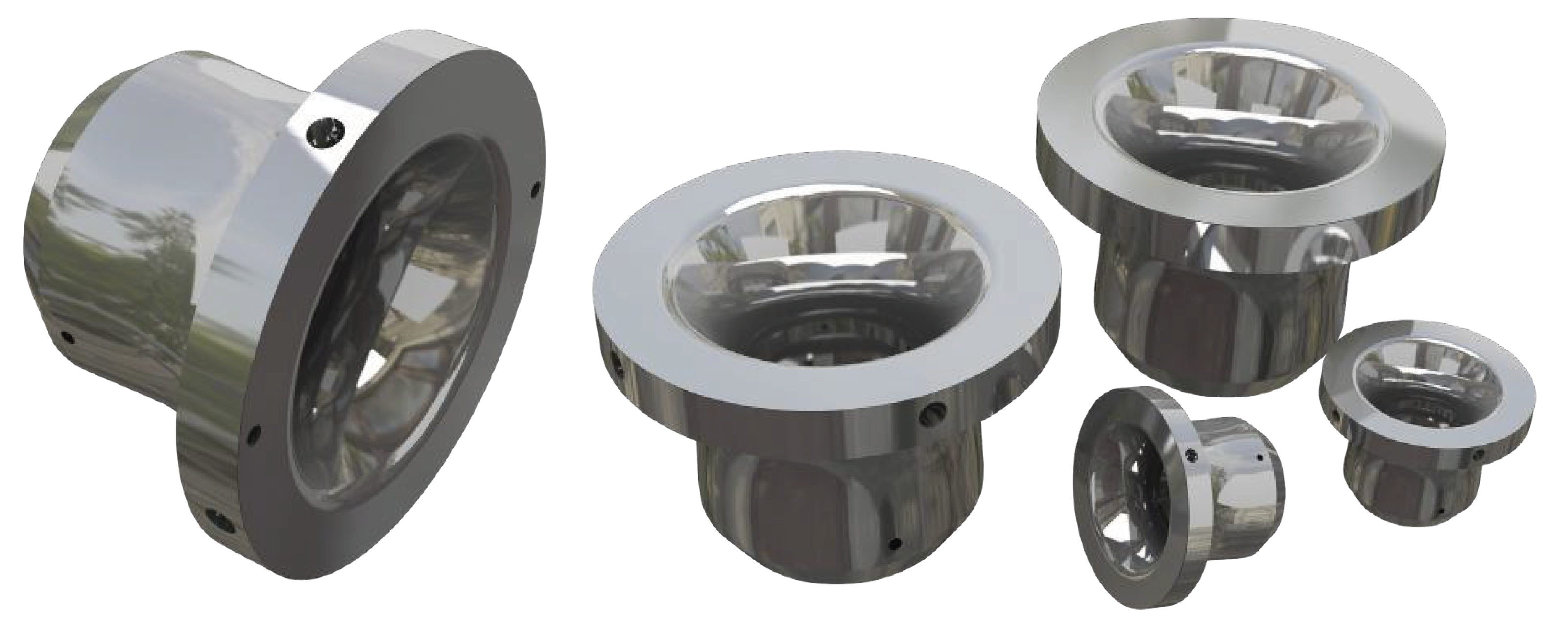

Nozzle Flowmeters

The Flow Nozzle is generally used for the measurement of liquid or gas flows including steam, non-viscous, erosive and high-velocity media. It does not rely on a sharp edge (which can deteriorate over time) to maintain accuracy and therefore offers excellent long-term accuracy with less wear, reducing the possibility of measurement error over time.

Flow nozzles are capable of measuring higher flow rates, often double, than an equivalent orifice plate at the same differential pressure. The flow nozzle is available in various designs including mechanically clamped between flanges or permanently welded directly into the pipe line.

Balance Flowmeters

The balanced flowmeter is a special differential pressure flowmeter. It uses unique Reynolds number to increase the thickness and machining accuracy of the throttle. Its flow performance is close to that of the venturi tube, with simple and safe structure and qualitative leap in performance.it minimizes eddy currents, reduces energy (pressure) losses by 50%, and measures higher altitudes than standard orifices with 34% greater accuracy.

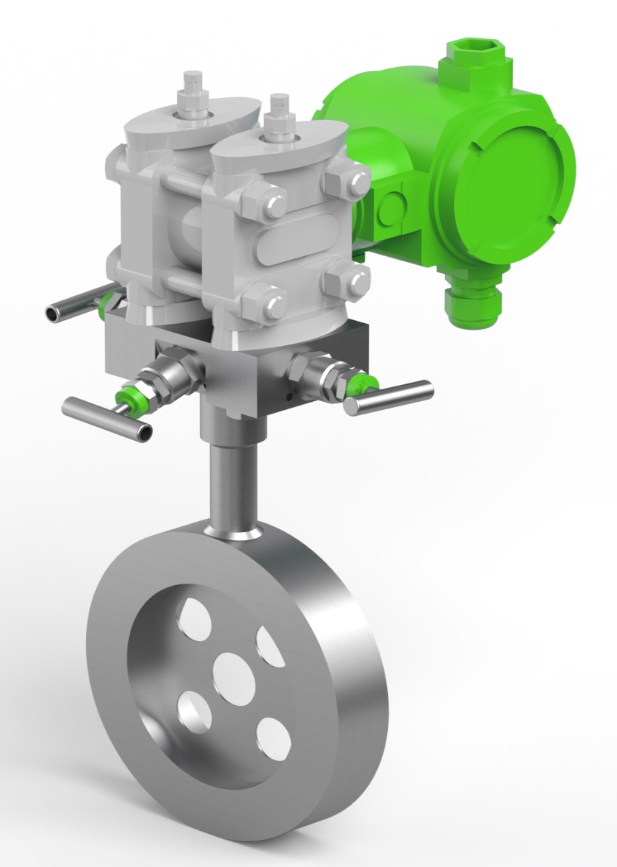

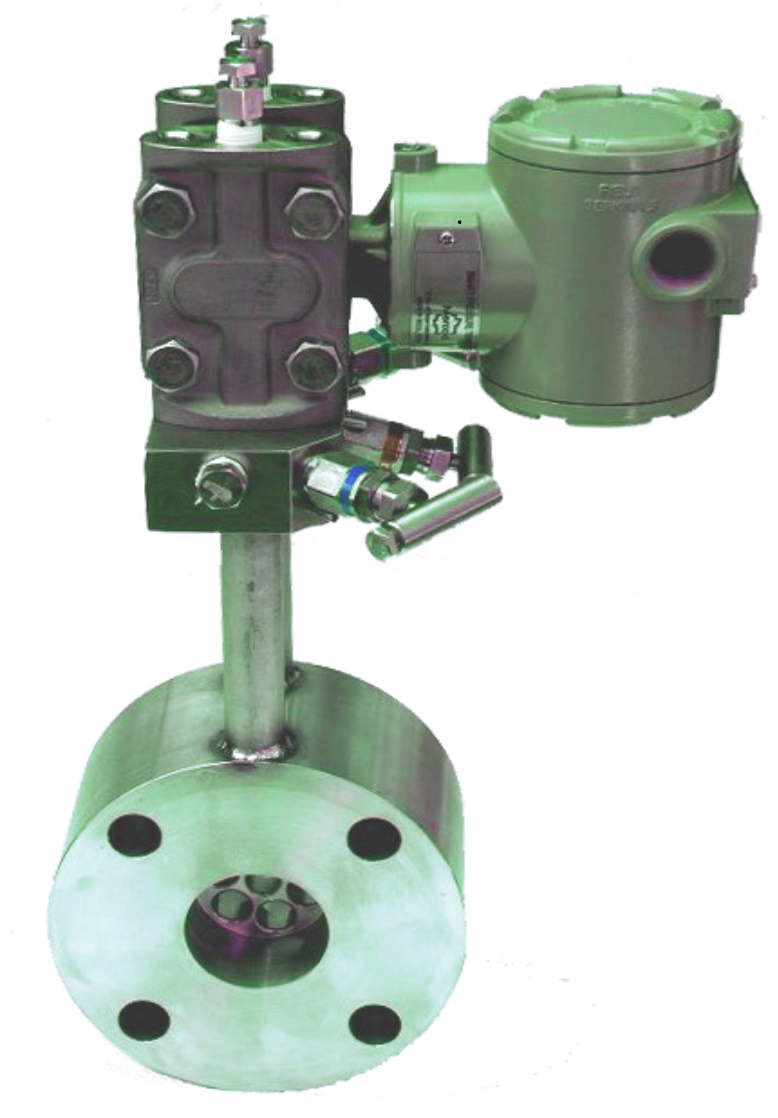

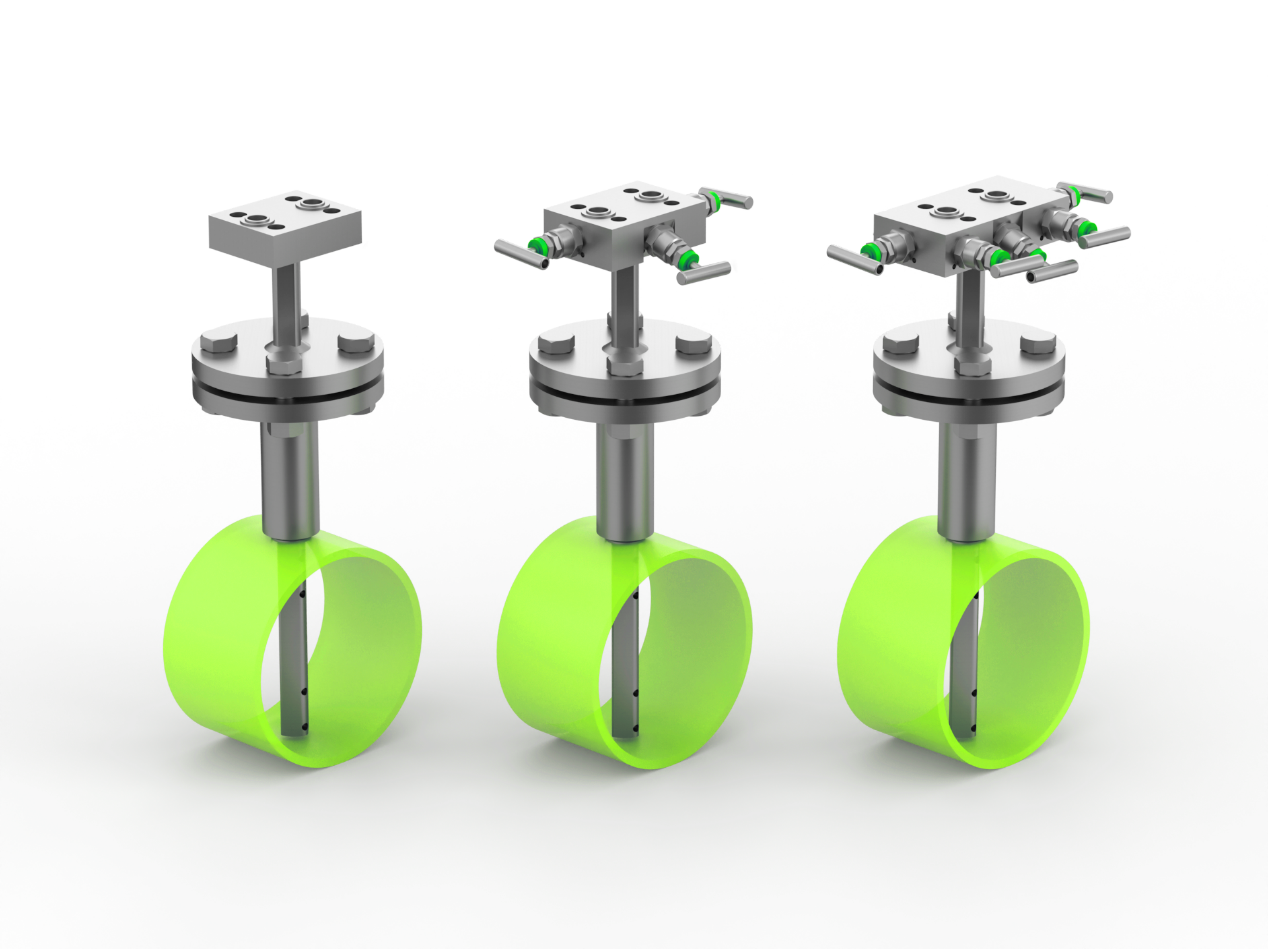

Cone Flowmeters

Differential Pressure Flow Meter, Ideal for Liquid, Steam or Gas Measurement Built In-Flow condition design ideal for use in tight-fit and retrofit installations.

V-Cone Flow Meter is an advanced differential pressure instrument, which is ideal for use with liquid, steam or gas media in even the most challenging conditions.

The V-Cone flow meter’s unique design provides repeatable accuracy of up to ±0.5% of rate under even the most difficult flow conditions.

Designed for mild to harsh operating environments, this advanced flow meter consistently outperforms traditional differential pressure (DP) devices, and other flow technologies.

Can be installed virtually anywhere in the piping system, or easily retrofit into an existing piping layout giving significant cost savings.

Long-term performance assurance with no moving parts to replace and maintain.

Averaging Pitot Tubes

The averaging Pitot Tube is used for flow measurement for liquids, gasses, and steam in horizontal and vertical pipelines. Some of the main advantages of the averaging Pitot tube are that it has a very low installation cost and the permanent pressure loss is low compared to other flow instruments.

In addition, the Pitot tube is probably the most cost effective solution on the market regarding differential pressure flow measurements in stacks and chimneys. From 1” to 240” pipes, remote or direct transmitter mounting, the averaging pitot tube offers accurate repeatability for your flow measurement needs.

Special

Our company specializes in the design of corresponding instruments and valves for users’ special working conditions.

If you have any questions in this respect, please contact us.